Technical Information

We are doing our best to become a future-oriented company.

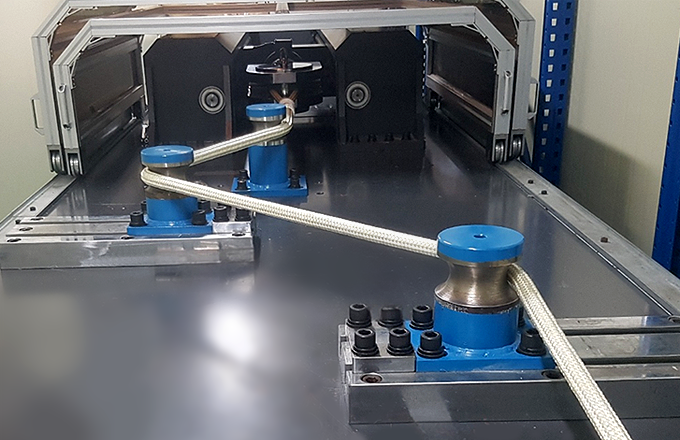

Cutting edge equipment and innovative research and development

R&D FIELD

We are developing even safer and stronger synthetic fiber ropes based on our cutting edge equipment and continuous technological innovation.

- Optimal solution for each industrial requirement with thorough verification of performance in different working conditions

- Innovative technology, Stringent quality management, continuous research and development

- High performance fiber ropes with high global competitiveness provided

TEST Information

-

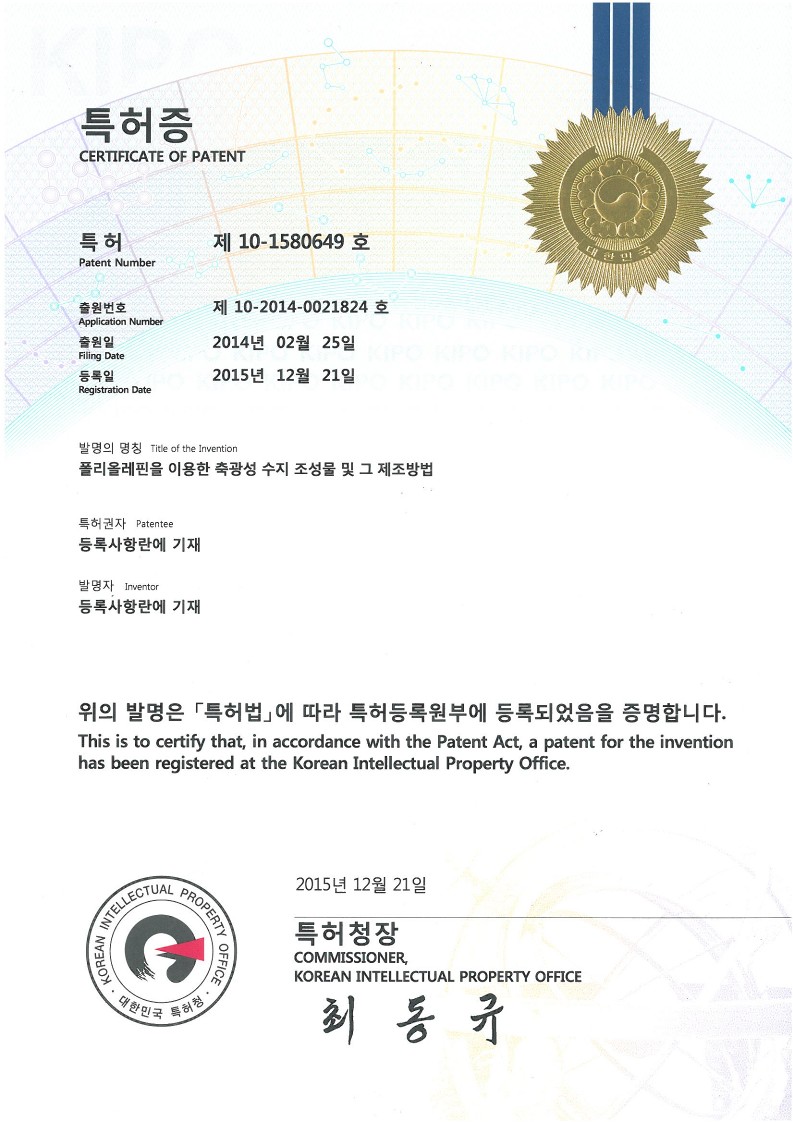

Non take-up winder of extruding

No 10-1580649 Date 2015.12.21 -

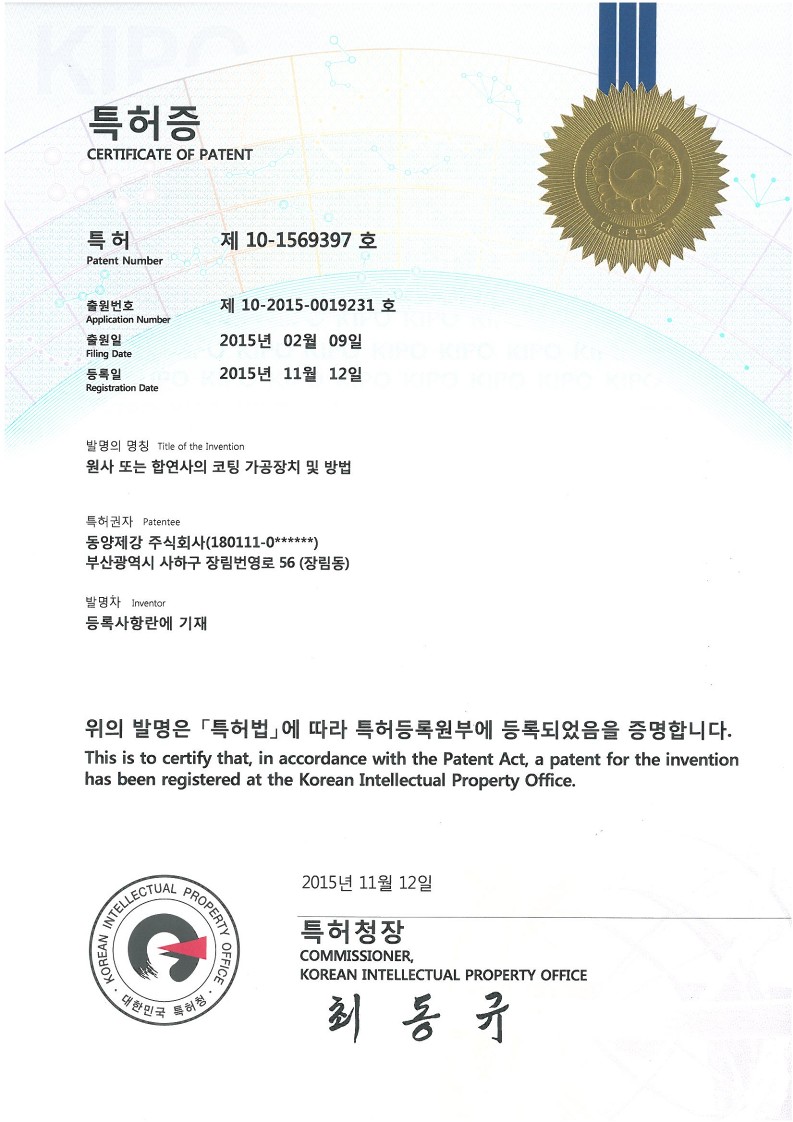

The coating device & method of yarn or twisted yarn

No 10-1569397 Date 2015.11.12 -

Plaited running resistance rope

No 10-1553326 Date 2015.06.09 -

Double rope using synthetic resin film

No 10-152882 Date 2015.06.09 -

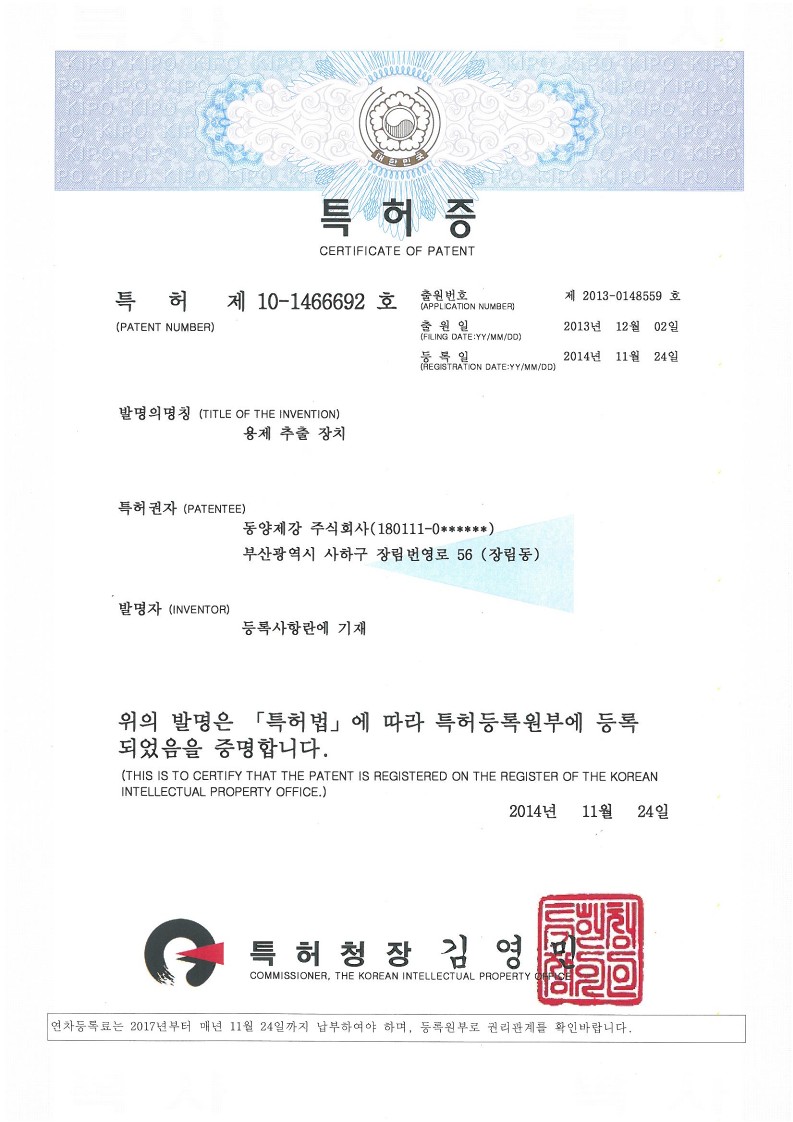

Solvent extraction device

No 10-146669 Date 2014.11.24 -

The manufacturing method of tube type rope & end product

No 10-1285563 Date 2013.07.08 -

Gel spinning pack

No 10-1186006 Date 2012.09.19 -

Tube type rope with improved abrasion resistance and antifouling property

No 10-1150720 Date 2012.05.22 -

Rope protection cover enabling visual check of inner part

No 10-1113597 Date 2012.02.01 -

Braiding machine having capability of changing rope structure

No 10-0954753 Date 2010.04.19 -

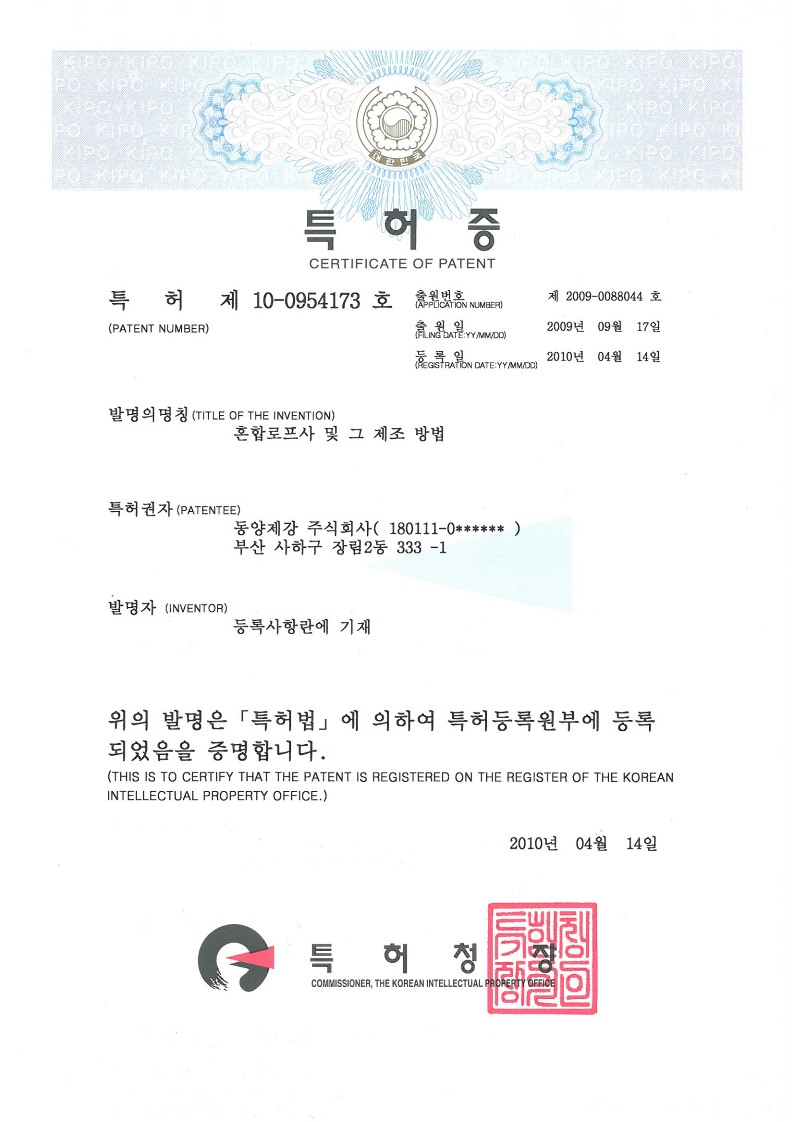

Composite rope yarn and method of preparing the same

No 10-0954173 Date 2010.04.14 -

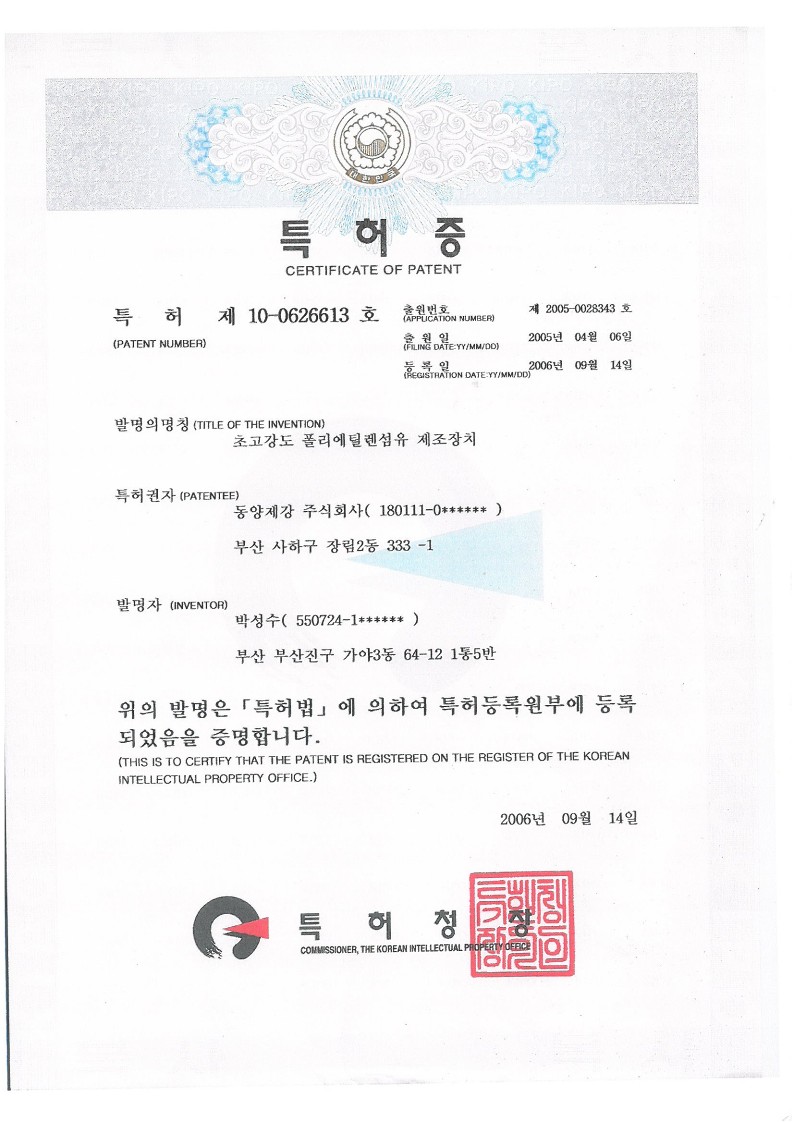

Ultra High Strength Polyethylene Manufacturing Machine

No 10-0626613 Date 2006.09.14 -

Anti-vibrator of spindle on twisting bobbin

No 0246728 Date 2001.09.04 -

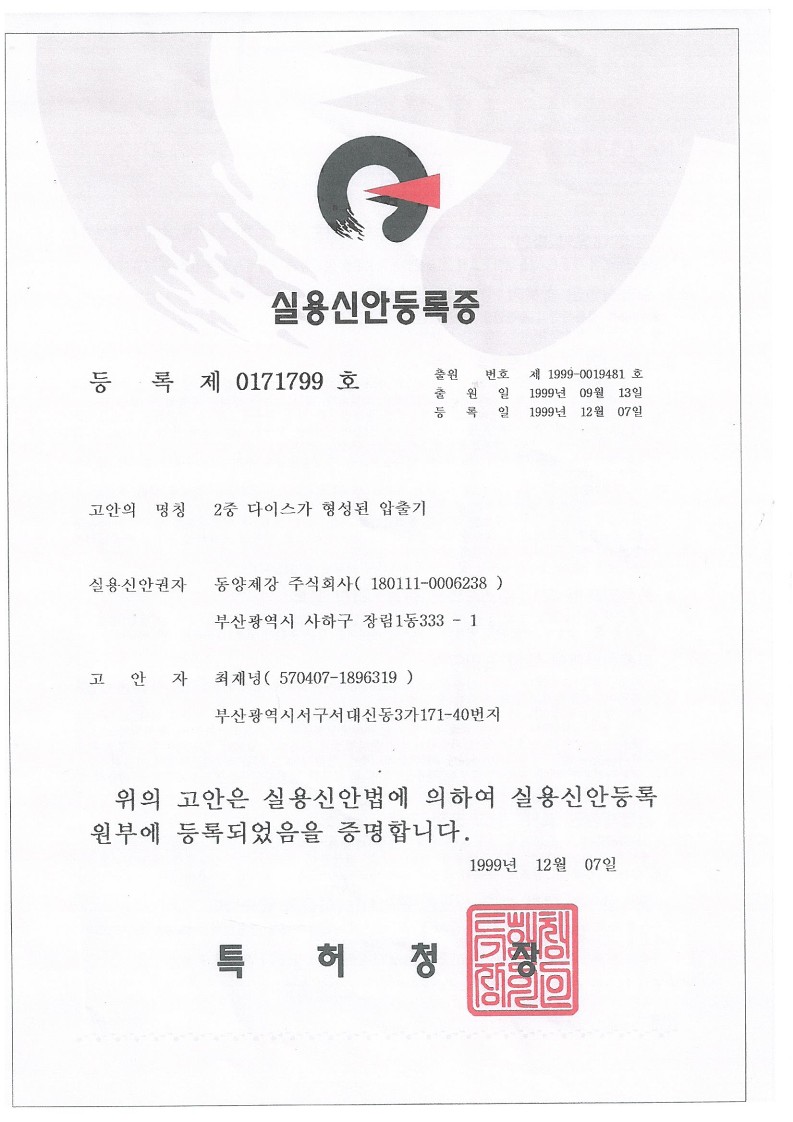

Twin-head extruder

No 0171799 Date 1999.12.07 -

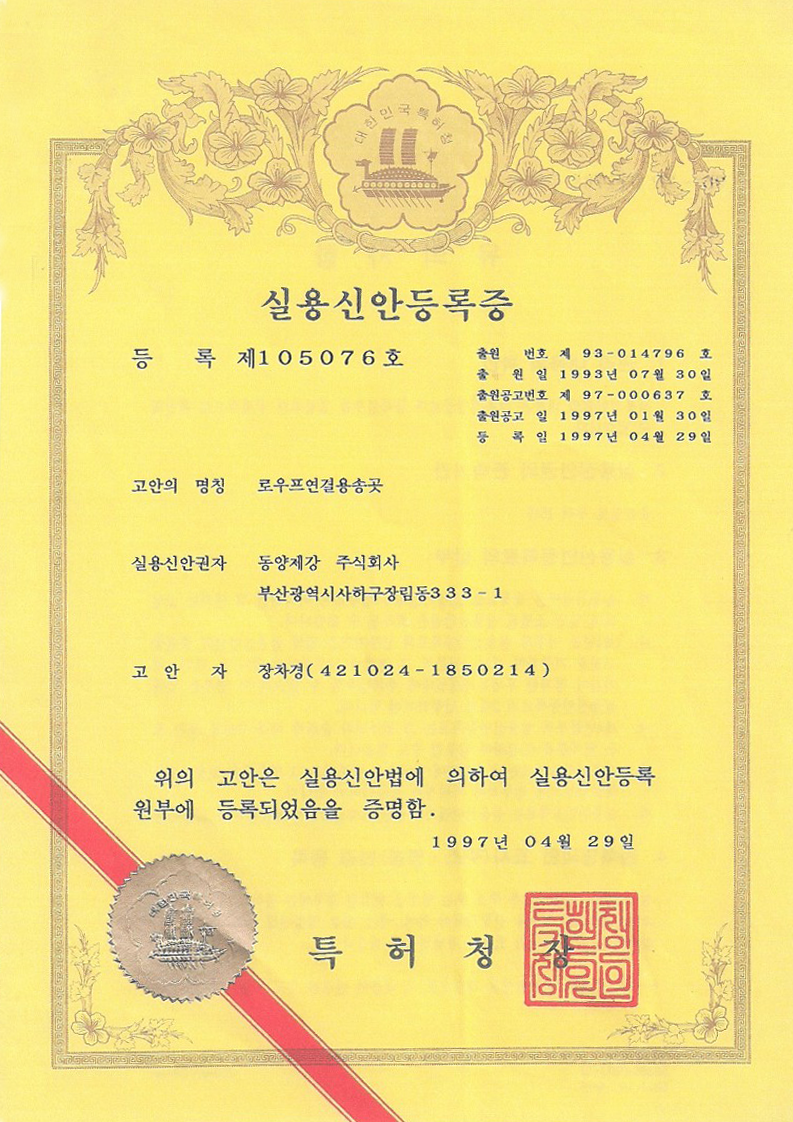

Eye-splicing tool

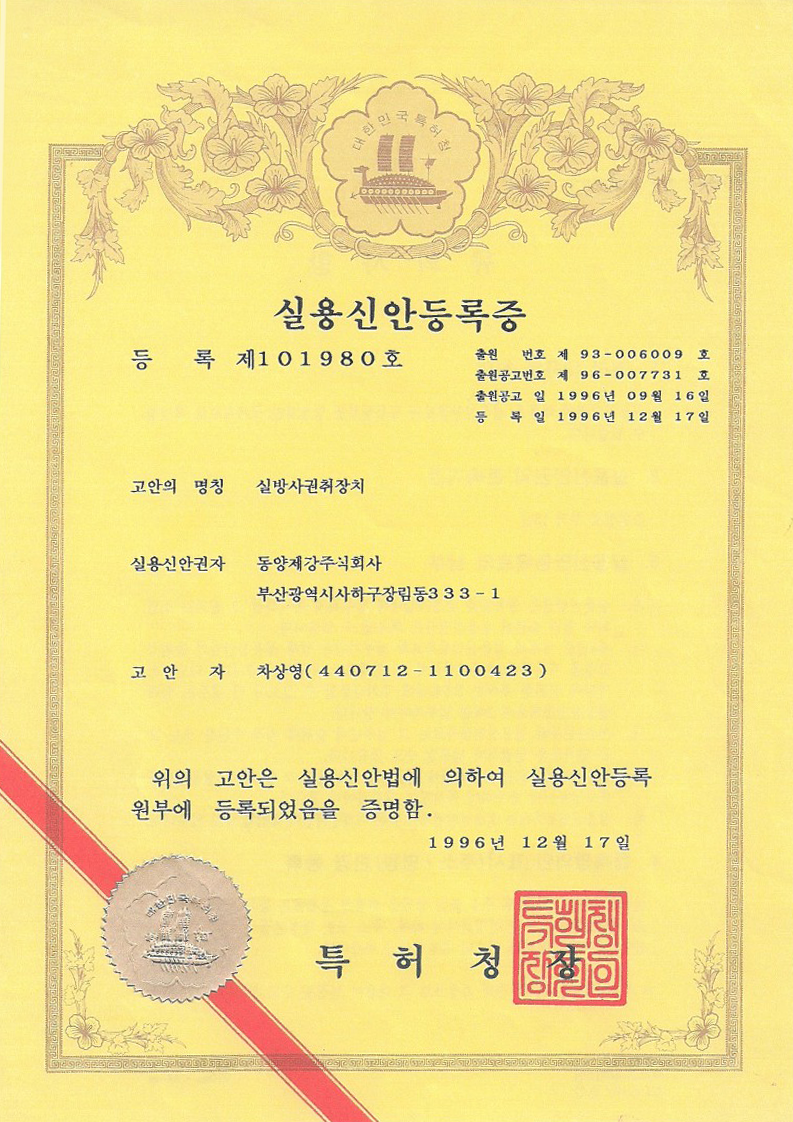

No 101980 Date 1997.04.29 -

Non take-up winder of extruding

No 101980 Date 1996.12.17

Policy Privacy

You have the right to refuse consent to the collection and use of personal information below. However, if you do not agree with it, it could be limited to use some services.

Personal information collected

Company name, name of person in charge, contact information, email address, inquiry details and etc.

Purpose of collection and use

The information you enter will not be used for any purpose other than providing consultation and answers to inquiries.

Retention and use periodv

Collected personal information is stored for 5 years after completion of consultation and then destroyed.

Provision and entrustment of personal information

Collected personal information is not provided to or entrusted to third parties